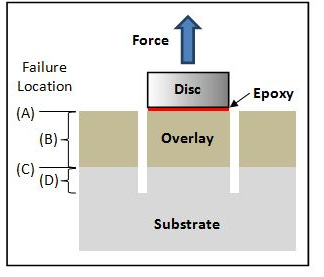

Concrete pull-off testing is used to measure the direct tensile strength of a material or bond strength of an interface. The concrete pull-off testing equipment consists of a metal test disc, epoxy, core drill, draw bolt, and jack. First, a shallow core is drilled perpendicularly into the surface leaving the intact core still attached to the material at the area of interest. Next, a metal test disc of the same diameter as the core is epoxied/bonded to the surface of the attached core. Once the epoxy cures, a bolt is attached to the metal test disc and the jack, shown in Figure 1, pulls the bolt/disc until failure occurs. The load at failure as well as the location of the failure is recorded. Failure can occur in any one of the following planes: (A) epoxy, (B) overlay (if applicable), (C) interface, or (D) substrate, as shown in Figure 2.

Concrete pull-off testing is used to confirm the substrate strength prior to the installation of repair materials or as quality assurance for the installation of overlays or fiber wrap. Such testing follows ASTM C 1583, Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method). Using this type of testing for quality assurance ensures that clients receive an adequate, well-constructed repair.