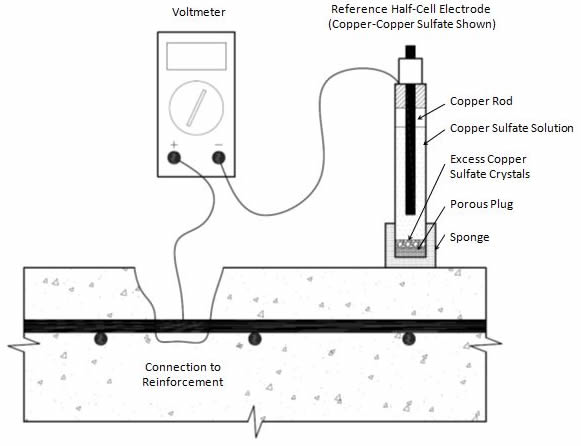

Half-cell potential testing and resistivity testing are used to estimate the likelihood of active corrosion in reinforced concrete structures. This testing is typically conducted on a grid with the spacing varying depending on the structure type and the size of the area to be scanned. Carrasquillo Associates' (CA) equipment can measure both half-cell potential and resistivity. It consists of a reference half-cell electrode, typically copper-copper sulfate, a voltmeter, and connecting wires. The equipment setup is shown schematically in Figure 1. As seen in Figure 1, minor destructive work is required to connect to the reinforcement. The half-cell potential testing is covered in ASTM C 876, Standard Test Method for Corrosion Potentials of Uncoated Reinforcing Steel in Concrete. The area to be tested must be electrically connected and may need to be pre-wetted. The area to be tested should be relatively sound with minimal spalls and delaminations.

CA prefers to complete half-cell potential testing and resistivity testing simultaneously because both sets of data are useful for assessing the corrosion potential in a structure. Half-cell readings show the relative likelihood of corrosion and resistivity shows the relative ease with which corrosion can occur. In other words, if the resistivity is high, corrosion can still occur, but it will occur less easily and therefore at a slower rate. The opposite is also true. If the resistivity is low, the rate of corrosion will likely be higher.

CA typically displays results of the half-cell potential testing and resistivity testing on contour maps. CA examines the gradients in the contour maps because areas with a higher gradient usually exhibit a high likelihood of active corrosion. Areas with high likelihood of active corrosion can be further tested and/or exploratory openings can be made to visually check the reinforcement.

Figure 1: Schematic of Half-Cell Potential Testing