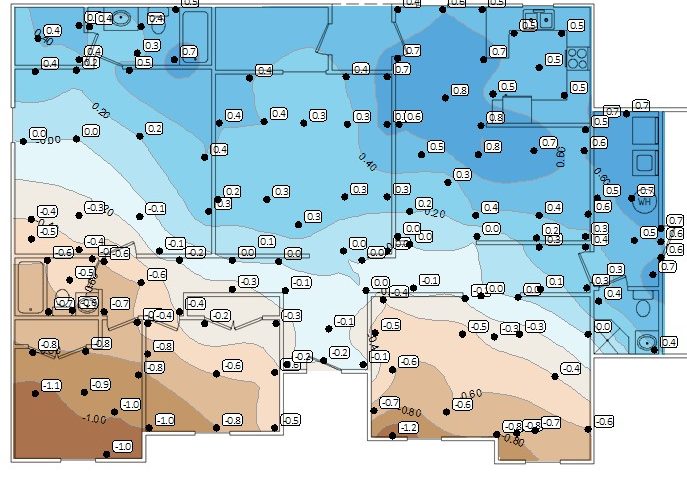

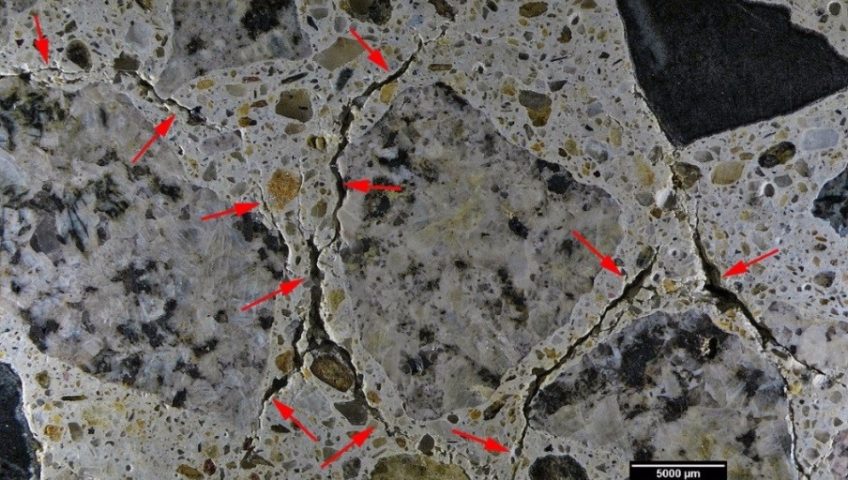

CA investigated whether the alleged distress at 28 residences located in Peñitas, Texas was the result of drilling operations which occurred in the area between 2007 and 2011. The investigation included a detailed condition survey of each residence as well as an elevation survey of each residence’s slab-on-grade foundation. CA reviewed applicable industry standards and relevant published literature regarding ground vibrations and damage to existing structures. The investigation did not produce any evidence to support the conclusion that the alleged distress in the residences was the result of ground vibrations from the drilling operations. CA determined that the observed distress in the residences was most likely caused by one or a combination of the following: dimensional movement of the structure due to temperature and humidity cycles, drying shrinkage stresses, foundation movement, and/or deficient construction.