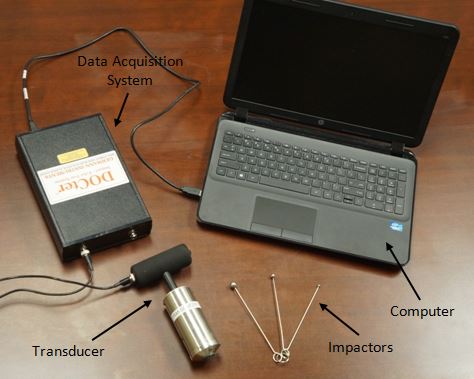

Impact-echo testing in concrete can be used to locate defects, such as voids, honeycombing, delaminations, and cracks. It can also be used to determine the thickness of concrete elements and to estimate the depth of cracks in concrete structures. Impact-echo testing equipment consists of an impactor, displacement transducer, data acquisition system, and computer, as shown in Figure 1. Impact-echo is a stress-wave technique that uses an impactor to impart a stress wave into the surface and the reflections of the wave are felt by the displacement transducer and recorded by a computer. The method uses the relationship between wave speed, time, and thickness to confirm the presence of defects and the depth to the defects. Impact-echo testing is specialized with a slow rate of scanning; therefore, it is best suited for areas that have been identified as suspect using visual observations, ground penetrating radar, ultrasonic pulse velocity, and/or a delamination wheel.

Figure 1: Impact-Echo Testing Equipment