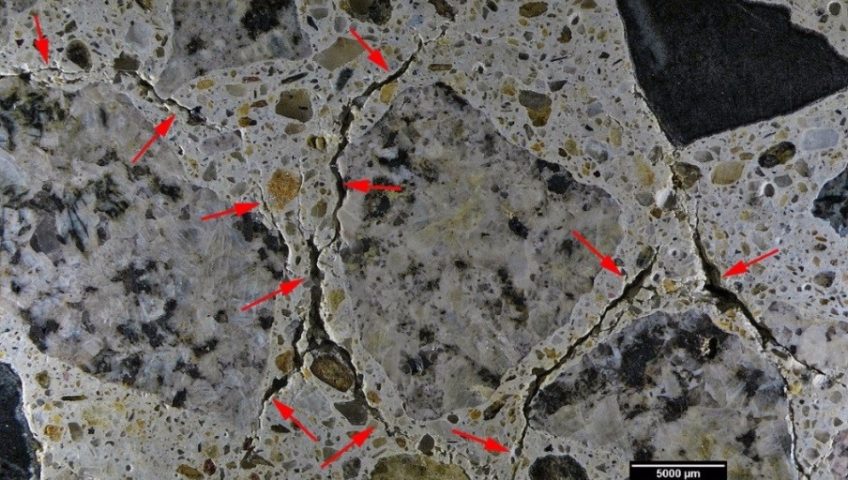

CA investigated allegations that the characteristics of the concrete mixture and properties of the as-delivered concrete caused numerous post-tensioning blowouts and delays during construction of a seven-level parking garage. CA’s investigation focused on investigating the concrete mixture design’s conformance with the design requirements, the quality and suitability of the as‐delivered concrete for its intended purpose, and if the concrete caused and/or contributed to the alleged delays and blowouts experienced during construction. CA determined that the ready-mix supplier’s concrete mix design submittal was in compliance with the design requirements for the construction of the parking garage and was approved by the engineer of record. CA’s investigation into the materials, proportioning, production, mixing, and delivery of the fresh concrete and its characteristics and performance did not reveal any evidence to support the allegation that the concrete produced and delivered was the cause of or a contributing factor to the alleged delays and blowouts during post‐tensioning. CA found that the blowouts were the result of any one or a combination of the following deficiencies within the responsibilities of the general contractor: in‐place concrete early‐age protection and curing during cold weather, curing and handling of field‐cured cylinders, concrete placement quality, and installation of reinforcement.