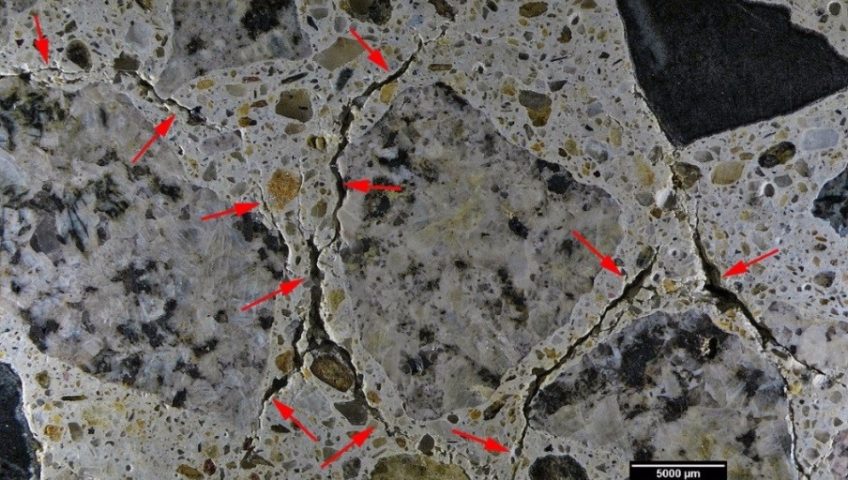

CA investigated the structural integrity of a 275,000 gallon municipal water tank in Vermont. The water tank consisted of a cast-in-place concrete foundation slab, cast-in-place concrete walls, and a precast, hollow-core plank roof with a continuous cast-in-place concrete topping slab over the planks. After only about ten years in service, distress was noted on the underside of the precast, hollow-core planks in the form of cracking and fractured and fallen sections of concrete. CA investigated the distress and alleged failure of the water tank. CA focused on the structural system, construction, and condition of the water tank as well as determining the cause(s) of the observed distress. CA reviewed construction documents, construction specifications, previous engineering and petrographic summary reports, and relevant published literature and industry standards. CA’s field observations, sampling, and petrographic examination revealed that the overall tank structure was in good condition and that the distress in the roof structure was due to an internal sulfate attack mechanism. CA determined that the distress mechanism emanated from planks’ manufacturing process.