Slab-On-Grade Distress Investigation and Analysis

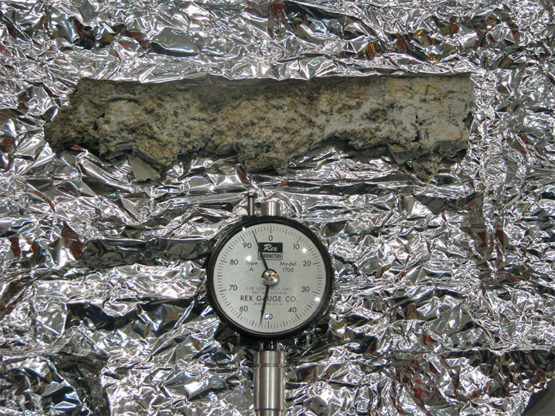

The project consisted of two aircraft assembly hangars consisting of 8 in. thick cast-in-place slabs-on-grade with 0.5 in. wide and 2 in. deep joints. The facilities were constructed during the period from 2004 to 2005. CA was retained to conduct an investigation and determine the cause(s) of the distress occurring at the joints that consisted of the joint sealant protruding up to a 0.5 in. above the surface of the slab-on-grade. CA’s investigation consisted, among others, of several site visits, concrete core sampling at the joint sealant locations, shore hardness testing, evaluation and different joint sealant, test program, and condition surveys. CA determined the cause(s) of the distress and provided recommendations for remediation of the distress including material selection and installation procedures and recommendation for joint detailing for future construction.

The project consisted of two aircraft assembly hangars consisting of 8 in. thick cast-in-place slabs-on-grade with 0.5 in. wide and 2 in. deep joints. The facilities were constructed during the period from 2004 to 2005. CA was retained to conduct an investigation and determine the cause(s) of the distress occurring at the joints that consisted of the joint sealant protruding up to a 0.5 in. above the surface of the slab-on-grade. CA’s investigation consisted, among others, of several site visits, concrete core sampling at the joint sealant locations, shore hardness testing, evaluation and different joint sealant, test program, and condition surveys. CA determined the cause(s) of the distress and provided recommendations for remediation of the distress including material selection and installation procedures and recommendation for joint detailing for future construction.