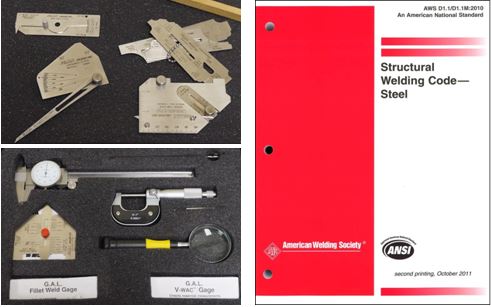

Building codes generally require that all welds be visually inspected to ensure the strength of the connections and ultimately the safety of the users. Most weldments in building structures generally fall under the American Welding Society (AWS) D1.1 Structural Welding Code -Steel. Carrasquillo Associates (CA) employs engineers that are Certified Welding Inspectors in addition to being licensed professional engineers. This unique combination of education, experience, and certification/licensure allows CA to have great insight into the causes and effects of welding quality on the end structure. Visual inspection of welds reveals surface flaws and is a valuable indication of the quality of weldments. It is quick, simple, and relatively low cost compared to other forms of welding inspection, but it does require trained inspectors. It should be noted that visual inspections are limited to the exposed surfaces of the weldments and that subsurface discontinuities may not be detected. Visual inspection typically entails measuring different parts of the weldment utilizing specialized tools, as shown in Figure 1, and taking note of any discontinuities that could prevent the weld from being code compliant. Items that are typically checked include porosity, slag inclusions, undercut, undersized weld, overlapping weld material, arc strikes, and incomplete fusion, among others.

Figure 1: Visual Weld Inspection Tools