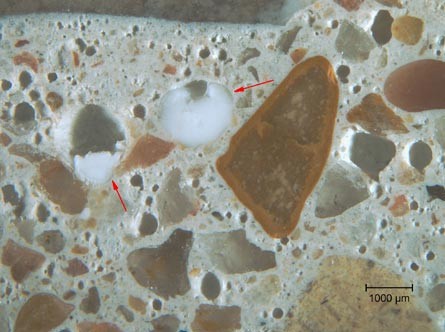

CA performed a forensic engineering investigation to determine the cause(s) of the distress observed in the exterior concrete slab-on-grade driveways and sidewalks of numerous homes in a single family residential neighborhood. The observed distress consisted of surface discoloration, pop outs, and peeling of the membrane coating, which was installed on several driveways in an attempt to remediate the distress. CA’s forensic investigation included, among others, visual inspections of more than 100 installations, concrete core sampling, and testing of the bond strength between the membrane coating and the concrete substrate. In addition, CA directed petrographic examination of several concrete cores sampled from the distressed and non-distressed locations in order to investigate any alkali aggregate reaction in the concrete. CA determined that alkali-silica reaction in the concrete was one of the cause(s) of the observed distress and developed recommendations for the concrete surface repair and remediation of the in-place concrete pavement.